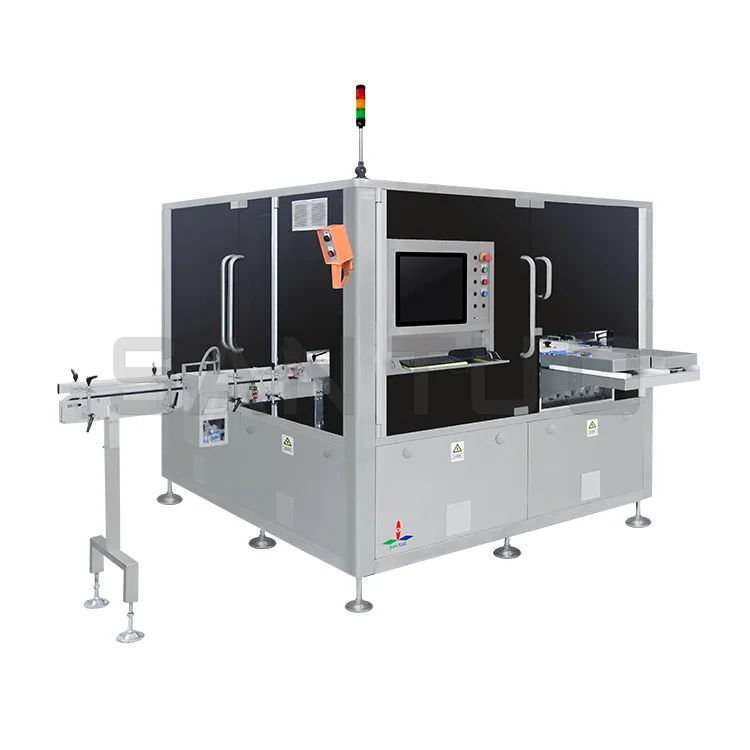

In the pharmaceutical and beverage industries, quality inspection plays a decisive role in ensuring product safety, compliance, and brand reputation. As manufacturing processes become faster and more complex, the demand for advanced inspection technologies has grown significantly. Among these innovations, the SANTUO's Gripper-type Inspection Machine has emerged as a high-performance solution that combines cutting-edge imaging, AI recognition, and precision detection to deliver unparalleled inspection accuracy.

What Is a Gripper-type Inspection Machine

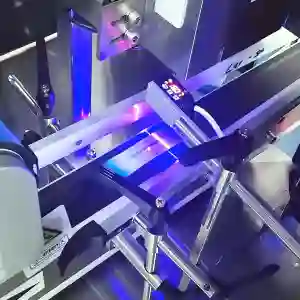

A Gripper-type Inspection Machine is an advanced automated inspection system designed to identify defects in containers such as glass or plastic bottles. Unlike traditional base-supported machines, it uses a suspended gripper structure combined with a bottle-rotating mechanism, eliminating blind spots caused by base obstruction. This ensures 360° imaging coverage of every inspected product.

By leveraging AI-powered recognition, multi-spectral imaging, and high-speed detection, the Gripper-type Inspection Machine provides manufacturers with a robust tool for defect detection and regulatory compliance.

Key Advantages of Gripper-type Inspection Machines

1. Blind-Spot-Free Inspection

One of the most significant innovations of the Gripper-type Inspection Machine is its suspended gripper design. By eliminating the need for a bottom support, the system prevents any obstruction at the bottle base. Combined with a precise rotation mechanism, it enables complete 360° blind-spot-free imaging, ensuring that no area of the container is overlooked.

This capability is especially critical in detecting cracks, scratches, or micro-defects at the base of bottles, which are often missed by conventional inspection equipment.

2. AI Intelligent Recognition

Equipped with the Cognex AI vision system, the machine brings strong learning and self-improving capabilities to industrial inspection. Unlike traditional software-based systems, this AI-driven solution supports offline learning, which means data does not need to be uploaded to cloud servers. This ensures full data security while allowing the system to continuously refine its detection algorithms.

The AI can identify a wide variety of defects, including:

Cracks and scratches

Dents and deformations

Surface contamination

Visible foreign particles and impurities inside containers

Filling volume irregularities

By combining speed and accuracy, AI-powered recognition significantly reduces false positives and enhances production efficiency.

3. Multi-Spectral Light Source Technology

Another advantage of the Gripper-type Inspection Machine is its multi-spectral illumination system, which integrates both visible and invisible light sources. This allows the inspection system to penetrate translucent bottles and turbid liquid medicines with ease.

With this technology, the machine can clearly capture hidden defects and foreign materials such as:

Internal impurities

Glass shards

Microscopic contaminants that would otherwise remain undetected

This ensures comprehensive defect detection even in challenging product environments.

4. High-Speed and High-Precision Detection Architecture

The Gripper-type Inspection Machine employs high-performance line scan cameras that use line-by-line scanning for ultra-detailed image capture. Together with EtherCAT high-speed communication technology, the system achieves rapid data transfer and real-time processing.

Key performance benchmarks include:

Detection cycle of only 0.6 seconds per product

Precision of up to 40μm (adjustable)

This high-speed and high-precision architecture makes the machine perfectly suited for modern production lines that demand both throughput and reliability.

5. Verified by Knapp Test Procedure

To meet global regulatory requirements, the Gripper-type Inspection Machine complies with the internationally recognized Knapp test procedure. This validation framework is widely accepted by pharmaceutical regulatory authorities, including the US FDA and EU EMA.

By adopting Knapp test verification, manufacturers gain authoritative certification for their inspection process, ensuring compliance with stringent international standards while also reinforcing customer confidence in product quality.

Applications in Industrial Production

The Gripper-type Inspection Machine is versatile and finds applications across multiple industries:

Pharmaceutical Industry: Detects foreign particles, cracks, and filling defects in medicine bottles, ensuring patient safety.

Food and Beverage Industry: Ensures the integrity of bottles and cans, preventing contamination and maintaining product freshness.

Chemical Industry: Inspects containers used for hazardous or sensitive substances, minimizing the risk of leaks and product recalls.

By integrating this machine into production lines, companies significantly reduce manual inspection errors, minimize defective product rates, and optimize production efficiency.

Why Choose a Gripper-type Inspection Machine

As industries face increasing regulatory pressure and consumer expectations, investing in advanced inspection technologies is no longer optional—it’s essential. The Gripper-type Inspection Machine delivers unmatched performance through a combination of AI intelligence, blind-spot-free inspection, multi-spectral imaging, and ultra-precise detection.

By adopting this system, manufacturers not only achieve compliance but also elevate their operational efficiency, reduce costs, and protect brand reputation.

Conclusion

The Gripper-type Inspection Machine represents a new era of automated inspection, combining cutting-edge AI vision, advanced lighting, and precision mechanics into a single robust system. Its ability to deliver blind-spot-free inspection, secure defect recognition, and validated compliance makes it an indispensable asset for pharmaceutical, food, beverage, and chemical manufacturers.

In a competitive global market, adopting this technology is a strategic step toward improved efficiency, quality assurance, and sustainable business growth.