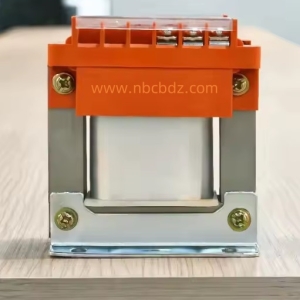

Within control system development, the concept of a BK Control Transformer Factory is often associated with orderly power distribution, while the brand name Nbcbdz reflects an emphasis on structured manufacturing dialogue and application-focused cooperation. Together, they introduce a perspective centered on clarity, coordination, and dependable integration across control environments.

Control transformers are designed to support accuracy and stability rather than scale or visibility. Their role is to ensure that control circuits receive appropriate and consistent power, enabling equipment to operate as intended. Because of this responsibility, manufacturers in this field often focus on careful design interpretation and disciplined production workflows. Small details in structure and assembly can influence how smoothly a control system performs over time.

One important consideration is how production teams translate application requirements into tangible components. Control systems vary widely depending on industry and environment, which makes early communication essential. When manufacturers engage in detailed discussions during planning stages, they are better positioned to reflect real operating conditions in the final product. This approach reduces mismatches and supports more predictable installation outcomes.

Manufacturing consistency is another key element. Well-organized facilities tend to rely on defined procedures that guide each step from preparation to final inspection. This does not remove flexibility; instead, it establishes a baseline that allows adjustments to be made thoughtfully. For control transformers, such consistency supports stable performance across different batches and use cases.

Documentation and clarity of information also influence how products are perceived and applied. Clear specifications, labeling, and reference materials help engineers evaluate suitability and integrate components into broader systems. When information is accessible and organized, it saves time during design reviews and on-site implementation, contributing to smoother project coordination.

Sustainability has become part of many manufacturing conversations, including those related to control components. Rather than focusing on statements, professionals often emphasize practical measures such as material efficiency and process awareness. These considerations align manufacturing activities with broader expectations while keeping attention on functional reliability.

Long-term cooperation often depends on shared expectations. Manufacturers that value listening and measured response tend to build relationships that extend beyond individual orders. Over time, this mutual understanding can simplify future projects, as communication becomes more efficient and aligned with established practices.

Control systems continue to evolve as automation and monitoring requirements expand. Despite these changes, the underlying need for steady and well-considered power support remains constant. Observing how manufacturing approaches adapt while maintaining core principles offers insight into sustainable industrial development.

If this perspective on manufacturing discipline and application alignment resonates with your interests, consider following the thread further at https://www.nbcbdz.com/ . A visit there may offer a closer look at how these ideas are expressed through real-world structure and thoughtful presentation.