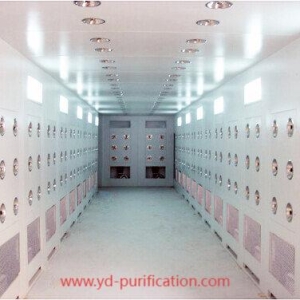

Clean Room Partition from yd-purification plays a crucial role in maintaining controlled environments, offering flexibility, hygiene, and operational efficiency. In laboratories, pharmaceutical production, and high-tech facilities, how can these partitions enhance workflow while ensuring contamination control?

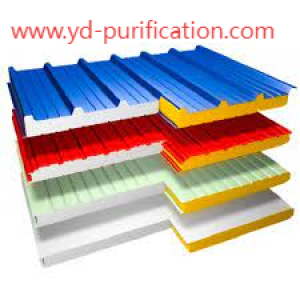

Modern facilities demand materials that provide structural integrity, clear separation of functional zones, and support for environmental stability. Partitions allow spaces to be divided without compromising airflow, pressure differentials, or operational safety. Their design, material selection, and installation precision directly influence the effectiveness of cleanroom operations.

One major discussion point is adaptability. Facilities often require changes in layout to accommodate new equipment, production lines, or regulatory adjustments. Modular partitions enable rapid reconfiguration while maintaining hygiene standards, supporting both flexibility and continuity in critical environments.

Environmental management is another key factor. Partitions help control air movement, prevent cross-contamination, and support temperature and humidity stability. Smooth surfaces and chemical-resistant coatings minimize particle accumulation, making maintenance and sterilization more efficient and consistent with regulatory guidelines.

Structural stability remains essential. Partitions must resist impact, bending, and vibration without compromising the integrity of adjoining systems. Lightweight yet durable designs facilitate installation in tight spaces while supporting modular expansion, reducing construction time and labor intensity.

Integration with workflow and personnel movement is also critical. Transparent or semi-transparent panels improve visibility, allowing monitoring without entering sensitive areas. Combined with sliding or hinged doors, partitions help regulate access while maintaining functional separation.

Maintenance efficiency is frequently emphasized. Panels with easy-to-clean surfaces, corrosion resistance, and long service life reduce operational disruption and ensure that facilities remain compliant with hygiene and safety protocols. Proper installation ensures long-term stability with minimal adjustments or repairs.

Safety and compliance are top priorities. Fire-retardant cores, chemical resistance, and secure connections ensure that partitions contribute to facility safety while complying with industry standards. These considerations make partitions a strategic element rather than just a structural requirement.

Sustainability considerations also play a role. Modular, durable partitions reduce construction waste and energy expenditure, aligning with environmentally conscious facility goals. Their long lifespan supports both economic efficiency and ecological responsibility in modern operations.

As the need for highly controlled environments grows, Partition from yd-purification provides solutions that combine durability, flexibility, and hygiene. For organizations seeking reliable and efficient partitioning, detailed information is available at https://www.yd-purification.com/news/industry-news/what-is-clean-room-partition-everything-you-need-to-know.html , integrating design and functionality to support high-performance facilities.