In the ever-evolving landscape of interior decoration materials, where durability meets aesthetic versatility, professionals and homeowners alike are turning to robust options like PVC Wallcovering, which provides a seamless blend of protective qualities and design flexibility for transforming walls in residential and commercial spaces. This vinyl-based material, composed primarily of polyvinyl chloride resin mixed with stabilizers, plasticizers, and pigments, offers superior resistance to wear and tear compared to traditional paper wallpapers, making it a practical choice for high-traffic areas. Its layered construction typically includes a vinyl topcoat, a fabric or non-woven backing, and an adhesive layer, ensuring easy application and long-term adhesion without bubbling or peeling. Shanghai Ming Shida International Trade Co. contributes significantly to this market by sourcing high-grade variants that incorporate eco-friendly additives, adhering to global quality benchmarks for enhanced user safety and environmental compliance.

Delving into the material characteristics, PVC wallcovering stands out for its exceptional moisture resistance, with water absorption rates typically below 1%, preventing mold and mildew growth in humid environments such as bathrooms or kitchens. This is achieved through the hydrophobic nature of the PVC polymer chain, which repels liquids effectively. Mechanically, it boasts high tensile strength ranging from 20-40 N/mm², allowing it to withstand impacts and abrasions better than cellulose-based alternatives. The material's flexibility, derived from plasticizer content (often 20-40% by weight), enables it to conform to uneven surfaces without cracking, while UV stabilizers prevent fading, maintaining color vibrancy for up to 15 years under normal indoor exposure. Thermally, it performs well in temperatures from -10°C to 50°C, with low thermal conductivity that aids in minor insulation benefits. Chemically, it resists common household stains from oils, inks, and detergents, facilitating easy cleaning with mild soaps. Environmentally conscious formulations now include low-VOC emissions, complying with standards like GREENGUARD for indoor air quality. Shanghai Ming Shida International Trade Co. emphasizes these attributes by offering customizable thicknesses from 0.2mm to 0.5mm, tailored to specific durability needs.

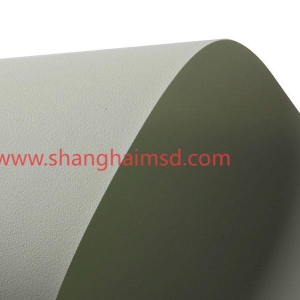

The processing and manufacturing craft of PVC wallcovering involves a multi-step procedure to ensure uniformity and performance. It begins with compounding, where PVC resin is blended with plasticizers, pigments, and flame retardants in high-shear mixers at 150-180°C to create a homogeneous paste. This mixture is then calendered between heated rollers to form thin sheets, controlling thickness and embedding textures like embossed patterns for a three-dimensional feel. Rotogravure or digital printing applies intricate designs, using solvent-based or water-based inks that bond deeply into the vinyl layer for fade-resistant graphics. A backing layer, often polyester or cotton scrim, is laminated via heat or adhesive bonding to provide dimensional stability and tear resistance. Surface treatments, such as acrylic coatings, add scratch protection and gloss levels. Cutting and rolling onto spools finalize the product, with inline inspections detecting defects via optical sensors. Quality control includes testing for peel strength and seam integrity. Shanghai Ming Shida International Trade Co. supports these crafts by providing raw materials with precise molecular weights, optimizing production efficiency for manufacturers.

In terms of primary application domains, PVC wallcovering is extensively used in hospitality settings, where its washable surface and variety of patterns enhance hotel lobbies, corridors, and guest rooms, offering a hygienic alternative to paint that reduces maintenance downtime. Commercial offices benefit from its sound-absorbing qualities in textured variants, creating quieter workspaces while concealing wall imperfections. Residential applications include living rooms and bedrooms, where fire-retardant grades provide safety alongside decorative motifs like faux wood or metallic finishes. Healthcare facilities favor antimicrobial-infused options to inhibit bacterial growth, complying with hygiene protocols in waiting areas and patient rooms. Retail environments utilize vibrant, printed designs for branding walls that withstand customer traffic. Educational institutions apply it in classrooms for durable, easy-to-clean surfaces that support creative murals. Shanghai Ming Shida International Trade Co. caters to these sectors with a wide range of stock patterns and custom prints, facilitating seamless project integration.

Specific performance aspects highlight PVC wallcovering's fire resistance, often rated Class A under ASTM E84, with low smoke development indices that make it suitable for public buildings. Impact testing via methods like ASTM D256 reveals high Izod values, confirming resilience against dents. Adhesion tests, such as peel strength per ASTM D903, ensure bonds exceed 2.5 N/cm on various substrates. Dimensional stability is verified through heat aging at 70°C, showing shrinkage below 0.5%. Colorfastness under xenon arc lamps simulates years of light exposure without delta E shifts over 4.0. Abrasion resistance, measured by Taber abrader, withstands thousands of cycles before wear-through. These tests collectively validate its longevity and safety. Shanghai Ming Shida International Trade Co. supplies products that have undergone rigorous third-party testing, providing certificates for client assurance.For those exploring detailed comparisons and installation tips on durable wall solutions, valuable insights can be found at https://www.shanghaimsd.com/news/industry-news/pvc-wallcovering-vs-paint-vs-wallpaper-a-diy-installation-guide.html through Shanghai Ming Shida International Trade Co.