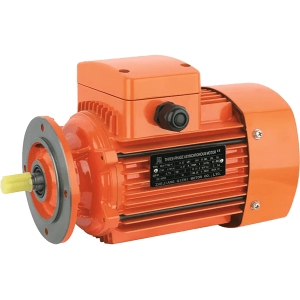

The robust construction of an Industrial Vibration Motor is engineered to endure the demanding conditions of continuous operation under significant mechanical stress. At its core is a standard electric motor, but its defining feature is the addition of one or more adjustable eccentric weights mounted on the extended rotor shaft at both ends. These weights are the source of the vibratory force. The motor's bearings are a critical component, specifically designed to handle the constant radial loads imposed by the rotating eccentric masses. They are typically oversized, high-capacity roller bearings with specialized seals to retain grease and exclude contaminants.

The housing is more than just a cover; it is a structural element that must transmit vibration efficiently. It is constructed from high-grade materials with thick walls to prevent resonance and fatigue cracking. The electrical components are protected against ingress from dust and water, with many motors rated to IP66 or higher. Thermal management is also vital, as the constant load can generate heat; designs often include external cooling fins or forced ventilation. For applications requiring variable force output, the eccentric weights can be manually adjusted—by changing the angle between multiple weights—to alter the resultant centrifugal force without changing the motor's rotational speed.

Maintenance focuses primarily on regular bearing inspection and lubrication according to the manufacturer's strict schedule, as bearing failure is the most common cause of downtime. The deliberate over-engineering of every component within an Industrial Vibration Motor is what guarantees its operational longevity. This focus on durability and serviceability ensures the motor can deliver consistent, reliable vibratory force as a "set-and-forget" component in industrial machinery for thousands of hours.